It’s no secret to growers that high-THC content in cannabis means better wholesale prices and better sales at the retail level. But reliably hitting the target range can be difficult, even in greenhouse conditions.

While the importance of the genetics of high-potency strains is well known, other factors like lighting strength, light wavelength, light tapering at flowering time, nutrients, timing of harvest, and after-harvest processing and storage also play important roles.

To make sure all these factors are working as planned, however, you need to keep testing throughout the growing process.

As THC numbers climb higher and higher with the appearance of new cultivars and the refinement of processes, it’s more important than ever before to ensure that your product is highly potent. For cannabis growers, and perhaps for the industry as a whole, the stakes have never been higher.

By the Numbers

Consumers are the primary driver behind the need to achieve and maintain higher THC levels. In digital and brick-and-mortar dispensaries, labels inform shoppers about cannabinoid percentages (as they should), often with THC percentage highlighted. A “more THC is automatically better” mentality has taken hold, however, with some customers making purchasing decisions based primarily on THC numbers.

In this article, a grower is quoted as saying, “If I have something that’s super-fire that’s 19.1 (% THC), that’s borderline. If it was 18 or below, buyers try to negotiate the price down.”

Impact on the Industry

We’ve written about the risks of oversupply as the market matures and consolidates before. Currently, the cannabis inventory in Canada is at a record 1.4 billion grams.

MJBiz Daily recently wrote about how this oversupply is a factor in falling prices, which have forced licensed Canadian growers to destroy 26% of the 2021 crop. Notably, it was product quality that played a major role in the destruction:

“Most of that product is thought to be unsellable for various reasons, including poor quality or low THC scores.”

Another factor is regulations. In Canada, Health Canada regulations mandate that cannabis growers must destroy a minimum amount of product that is unlikely to be sold every month. There are a number of reasons for this, including prevention of theft.

The article clarifies that much of the oversupply isn’t in the dried flower market (which constitutes three-quarters of Canadian sales), but for extract products like vape pens.

The cannabis for these products is largely grown outdoors, whereas the cannabis for the dried flower market is typically produced in greenhouses. It is the outdoor canopy that has grown since 2018, not the indoor production, which has stayed consistent.

Test, Test, and Test Again

How can growers ensure that their product has that high-THC number that sells? As always, there’s no one silver bullet, and the solution involves testing multiple factors at several stages.

Testing of Crop Inputs

Potency testing is essential, but we can’t neglect testing for safety as well. When looking at suppliers, ask for a certificate of analysis, or COA. This ensures that materials from nutrient solutions to cleaning supplies are free from contaminants and contain what they say they contain. Doing a material review and doing small batch testing before using new inputs on full crops is also important.

Some growers, however, also do their own periodic testing of raw materials to ensure they’re free from contamination. If you can afford it, periodic water and soil contamination testing (heavy metals, microbial and mycotoxin testing) can save you from having to destroy entire crops.

Testing the pH levels of input materials can also help you fine-tune your process.

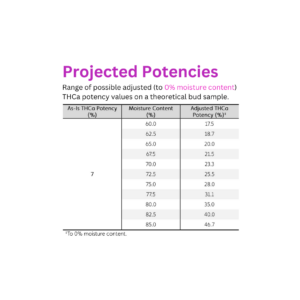

Potency Testing for Harvest Timing and for Pricing

Potency testing becomes critical as the harvest window approaches, approximately 8 weeks after flowering begins. While home growers can rely exclusively on trichome and/or pistil colour, commercial growers need to be more precise.

Testing to optimize harvest timing also allows you to contact buyers with your THC and other cannabinoid numbers earlier so you can have better discussions about pricing and get sales agreements in place faster.

Start to test flower samples two weeks before you think you should harvest, and see if the potency levels are appropriate to the potential of the cultivar. If the THC levels aren’t quite where they should be, wait and allow the plants to keep growing. (If you’re growing for more CBD and lower THC, testing like this also works, except that you would typically harvest earlier, before THC levels peak.)

Accurate sampling is also important. While smaller growers may be tempted to cherry-pick the best looking buds, it’s a practice that’s ultimately self-defeating because your best flowers won’t be representative of your crop. You don’t want to miss-time your harvest or accidentally report inflated THC numbers to a buyer (more on this in the section below).

To improve your odds of accurate sampling, divide your batch into a grid, and sample from different areas. You’ll soon learn the quirks of your growing area (maybe a low-lying part of an outdoor field gets slightly more water, or one side of an outdoor greenhouse gets slightly more daylight). Also be aware that THC levels can vary depending on whether the flower is at the top or the bottom of the plant.

As with any botanical products, it can be difficult to maintain consistency from batch to batch even once you’ve found the formula that optimizes your THC levels. Accurate data collection from every crop is essential to finding and fixing the small problems that can add up.

Avoid the Temptation to “Lab Shop”

Some producers who send samples to external labs engage in lab shopping. This is the practice of sending samples to different labs until they get the results they are looking for, whether or not those results are an accurate representation of the crop. Labs can feel pressured to deliver inflated THC results in order to keep their customers.

To counter this practice, regulators are implementing new accreditation requirements and ramping up inspections and auditing, and labs who have been too much of a helping hand to their customers have been shut down. Voluntary testing agreements between labs, including ring tests (in which every lab tests the same sample to identify outliers) have helped curtail this practice as well.

In some markets, wholesalers/distributors are required to have labs do testing under very strict conditions (for example, in California the lab employee must visit the premises to collect the sample or samples themselves).

Cannabis product manufacturers do their own testing of inputs, including your crop, as well as on products during different stages of manufacturing. Like you, they don’t want to have to throw away a batch. If something’s off, they’ll find out.

Putting Potency Testing Within Reach

Once your operation reaches a certain scale, a thorough roster of testing means that you’ll need your own testing solution, as mailing samples to external labs becomes prohibitively expensive. The challenge is that capital costs of building your own lab plus the ensuing production bottlenecks can make a centralized lab a less than ideal solution.

Ekidna’s rapid, decentralized solution puts more testing and better decision making to work for your operation. A rigorous quality control testing program will help ensure that your product meets the promise of your plants’ genetics.

Learn more about our solution >

Additional sources:

- https://www.leafly.ca/news/strains-products/lab-shopping-thc-inflation-marijuana-2019-leafly-review

- https://mjbizdaily.com/cannabis-products-present-unique-testing-hurdles/

- https://www.growopportunity.ca/cannabis-testing-101/

- https://cannabisretailer.ca/2021/a-peek-into-wholesale-pricing/

- https://cannabisretailer.ca/2022/record-high-canadian-cannabis-inventory/

- https://mjbizdaily.com/marijuana-experts-offer-strategies-to-maintain-quality-independent-of-lab-testing/

- https://mjbizdaily.com/how-cultivators-can-prepare-for-a-cannabis-harvest/