Where extractors are now, logistics, path planning and what you take with you.

How do the costs and timelines of off-site potency testing affect extractors’ day-to-day operations — and the saleability of their final product? Do these delays and expenses create a ripple effect some LPs may not have considered?

We sat down with former Christina Lakes Cannabis (CLC) President Rob Jones to understand the challenges at the heart of the lab testing status quo — and where real-time potency results can help.

Managing and trading agricultural commodities is no new endeavor for Rob, who has international experience expanding sales into new markets spanning 35+ years. We’re thankful for his time and thoughtful insight into all things extraction and testing!

Read the key questions and takeaways from our interview below:

Where extractors are now

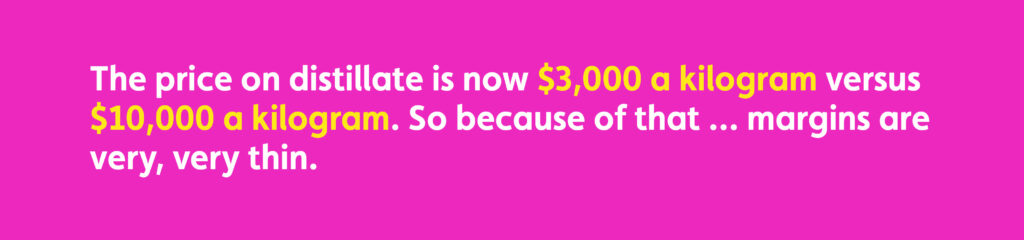

For a time, wholesale cannabis oil offered higher margins than dried flower cannabis in Canada. Is that still the case?

Two years ago, the price of distillate was $10,000 a kilogram. At that price, the margins were going to be fantastic … There wasn’t enough supply … and the demand was big, so the price was high. As the [indoor] growers started to grow more, there was more product available. So simple economics said there was too much supply and not enough demand, and the price dropped. The price on distillate is now $3,000 a kilogram versus $10,000 a kilogram. So because of that … margins are very, very thin.

Are there any challenges to potency testing during extraction, and could you speak to what those challenges are?

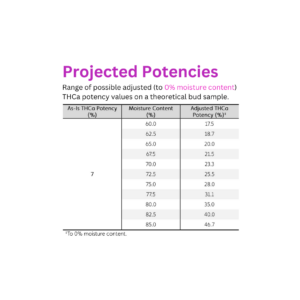

It was interesting because we had one strain that was phenomenal from the standpoint that it had THC, CBN, CBG and other cannabinoids. The problem was the market didn’t want those others, they just wanted THC … So that changed the whole entire concept — to grow product that was going to be high in THC and low in other cannabinoids… Testing the raw material is critical so you know you’ve got a base. That goes through the extraction equipment and comes out as an extract.

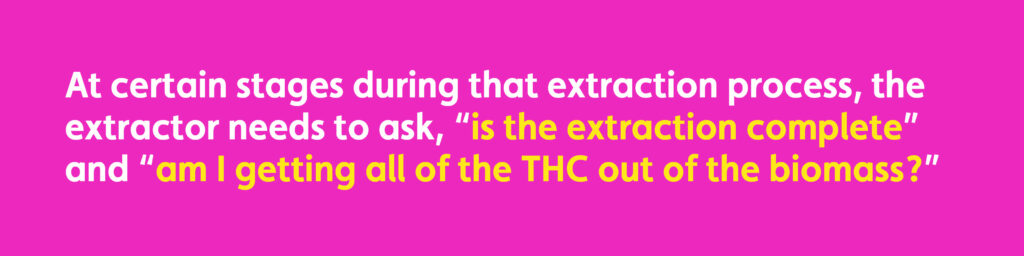

At certain stages during that extraction process, the extractor needs to ask, “is the extraction complete” and “am I getting all of the THC out of the biomass?” Right, so it’ll then go into Winterization, and you’re left with a winterized product. That goes to a third stage called Distillation… and you’re left with a THC level which is somewhere around 88 to 92% — trying to get to that 90% level of THC where vape producers and distillate users want the highest THC available.

You’d like to be able to test how much THC you’ve got at any different stage, because it’s going to save you time, save you money, and allow you to adjust your process. Maybe you need to leave it in longer, maybe you need more steam, maybe you need more pressure, maybe you need more temperature. So those are the types of things that make instantaneous testing paramount. We struggled at CLC for a year trying to finetune that system. So if we’d had lab testing available or Ekidna’s product available to us that worked and was reliable, we could have made decisions and probably saved a heck of a lot of money.

Logistics of testing during extraction

Testing throughout those different phases sounds like a lot of individual tests. Could you provide an estimate for how many samples CLC would need to send to the lab, per batch or per kilogram biomass?

At CLC, you would have as many as 25 tests a day [during different phases of the extraction process] just on THC, and I’m gonna say a minimum of 10 tests a day. So once you’ve got that batch of crude down that’s going into Winterization, you would take that sample and send it off to the lab. And then at Winterization, you do the same three days later. And then finally, you probably send two or three samples of your distillate.

What does that look like in terms of pricing and timelines, from when you send samples to the lab to when you receive results?

In that process, you say, “Okay, I’m going through the extraction, I need to test the extract,” so you take a sample, you send it off to a lab, and you’ve got 24-hour to 48-hour turnaround time just in transportation — just to get it to the lab. Once the lab gets it, they’re going to put it into a queue. If you want to expedite it, they can probably do a THC in 24 hours, but that’s probably going to cost you double, which is $500 versus $250. Then, for what we call in the industry a “certificate of analysis” to sell into the legal market, that is around $1,250 for a complete COA that gives you THC, pesticides, heavy metals, et cetera, et cetera — and that takes about two weeks.

Back to your point about adjusting processes as you go, what would the ROI be for rapid testing in terms of being able to optimize your system? If you’re getting 92% versus 88% THC, what does that get you in terms of saleability?

In the extraction process on a daily basis, each time you’d load the cylinders, that would be 60 kilos, so 30 in each cylinder, and it would take about two hours. If I’m extracting for two hours, and that gets me to 1% or less, if I go two hours and 30 minutes, I’m down to half a percent. Well, that’s not worth it. I’m better off emptying the cylinders and repacking them again. It’s a function of time so I know that I’m being efficient. The temperature’s right, the pressure’s right, and I’m extracting everything I can. If I’m getting that feedback from the test and I know how much is left from the biomass and how much my crude is, I can stop it and turn my equipment around a lot faster.

What about on the more valuable product side? If you’re selling at 88% vs. 92% THC, does that make a big difference to the bottom line?

It does, the 92’s going to sell a lot easier than the 88. The other thing…if you’ve got an 88 and a 92, you could do what we in the industry call “blend and extend” because the industry wants 90. So if I know I’ve got 88 and 92, I can take a blend and test it right there, knowing that if it’s 49% of this and 51% of that, I blend it together and get 90%. And boom, I’m done. Now, you…have to wait another two weeks to get your certificate of analysis back because you’d have to send it off to the lab. So if you get that instantaneous testing available, it allows you to blend finished products a lot easier. And then you can move it at the prescribed or the desired THC level.

So, rather than trying to get the highest possible extraction out, you’re trying to hit 90%, because that’s what everyone sells and buys?

Yeah, and the market changes because our largest customer had an A Grade and B Grade. So anything 85 and less, that’s what they were using for their infused pre-rolls. The higher-end stuff they were using for their vapes. So that was critical to have that high-end stuff. Being able to test at any point in time is critical.

Could you speak at all to personnel costs waiting for these results to come back, or is that not a cost issue that’s been considered?

Oh, it’s an absolute cost. Because you’re paying somebody, say, $30 an hour, and they’re standing around waiting for something. And [operationally] you would basically fly blindly for two weeks and say, “Oh, geez, I wish I would have known that because I wouldn’t have done [it that way].” So just that instantaneous ability to make decisions and say, “I’m on the right track, let’s keep going” or “I need to make an adjustment.”

Path planning: When is best to test?

Is there a certain stage where tests would happen more frequently, whether that’s on the biomass, after Extraction, or after Winterization?

I think each stage is critical. And I think that, you know — speaking specifically to CLC — they use the Orange Photonics, which seem to be okay for the dried flower, but as soon as the product gets up, and is more intense in the THC levels it struggles. So that’s why I think the Ekidna technology will give better results.

Throughout the whole entire process, I don’t know if there’s one more critical [stage] than the other. If I had to say there is one, it’s at the final end because…if you’re at 87% THC, and you’re gonna run another pass through it to get to 88.5%, you’re going to lose a certain amount. That’s where you have to make that call and say “I need to go and run them one more time.”

What you take with you: more yield

So, with rapid testing, will extractors preserve their yield?

Right. Yield is another thing that is critical… You are going to allow the extractor to increase their yield at each stage.

For example, if you take 1000 kilos of dried product, you’re going to go into extraction… Once the product comes out of Extraction, you’ve got crude oil. Let’s just call it 120 kilos of crude. And once you go into the next stage, which is Winterization — and you’re taking some of the fats and the waxes out of the plant material — you’re going to get down to say 90 kilos of winterized product. That will go into the third stage, which is the Distillation, and that will get you down to about 70 kilos of pure distillate, which is the product that you want to go into the vapes.

So with each of those stages, if you can take the 1000 kilos of biomass, and pull out 114 kilos of crude versus 120, and then you’ve got 110 of winterised, and 80, 85 or 90 at $3,000 a kilo for finished product — that’s what you’re trying to achieve. So the yield on each stage is critical. That’s why I think rapid testing is paramount for some of these extractors.

Thank you, Rob, for sitting down with us!

Want to know more about how Ekidna can help you? Book a demo!